| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Charmhigh |

| Model Number : | CHMT48VA (Vision System) |

| Certification : | CE |

| Price : | $4700 unit price (not including shipping) |

| Payment Terms : | T/T , Western Union, MoneyGram |

| Supply Ability : | 200pcs per month |

| Delivery Time : | 2-4 working days after received your payment |

CHMT48VA Desktop Automatic SMD / SMT Pick And Place Machine With

Vision System

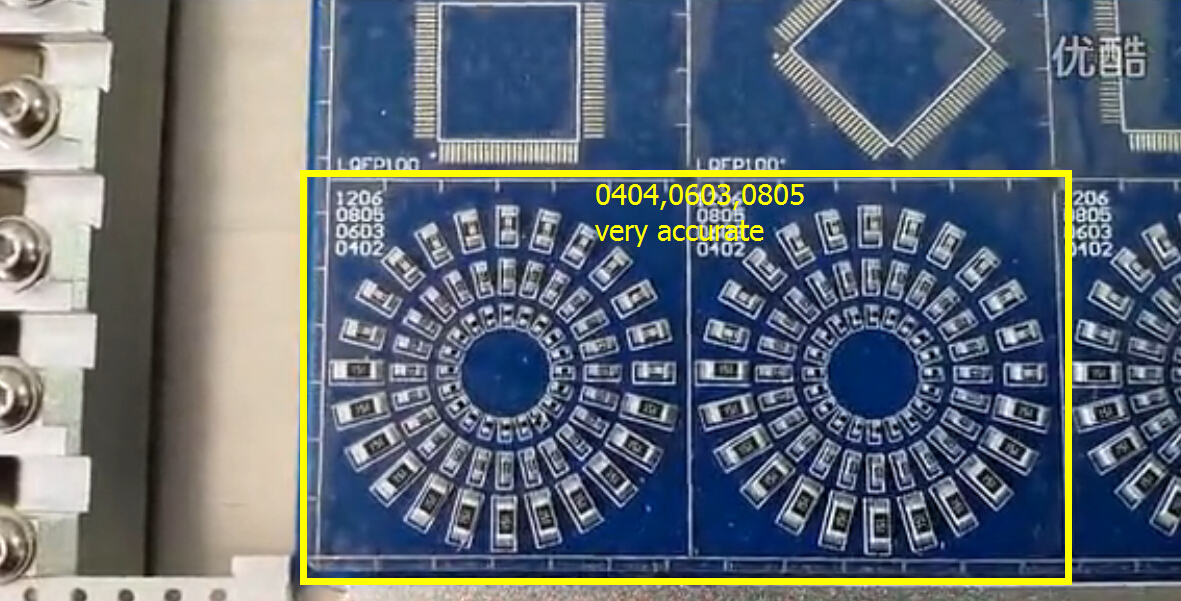

Place IC very accurate 110v 220V

Machine is completed, ready for work, each machine will be 100% tested well, QC passed.

Please purchase it with confidence.

Quality guarantee, quality is better than other brand machines.

Youtube links:

CHMT48VA Working video: (dual head 0402 0603)

https://www.youtube.com/watch?v=F-rcbhtZx84

CHMT48VA Placing IC :

https://www.youtube.com/watch?v=PE4gynczFvs

CHMT48VA exhibition video:

https://www.youtube.com/watch?v=cNGWnrLOSXA

Description:

SMT (surface mount technology) component placement systems,

commonly called pick-and-place

machines or P&Ps, are roboticmachines which are used to place surface mount devices (SMDs) onto a printed circuit board (PCB). They are used for high speed, high precision

placing of broad range of electronic components, like capacitors, resistors, integrated circuits onto the

PCBs which are in turn used in computers, consumer electronics as well as industrial, medical, automotive,

military and telecommunications equipment.

The new vison system CHMT48V is independent product of Charmhigh,

with advanced technology in

China, specail for research Lab, medium enterprise, Electronics enthusiasts or enterpreneur etc. It is small

with high precision, accurate positioning, easy operation with stable performance. Now leading the

technology in China.

CHMT48V feedback very well. Compare with previous model

CHMT28,CHMT36, it has a lot of

improvement, here are some highlights as follows:

CHMT48VA Vision System Specially Design with Vision Based Pick &

Place to achieve more accuracy and ensure for correct Placements on

Large Size of PCB/SMT/LED from Small to Max Size of Components and

PCB Size.1. Top Vision Camera to Identify PCB and Types of

Components, Optimised Data with Programs File2. Bottom Camera Check

each components before placements, it can check correct types

ofcomponents, correct angle, correct direction, flip components and

wrong pick Up, Missedcomponents.3. Vision system sending inspected

data and feedback to Programming processor, ProgrammingProcessor

give optimised command to machine get the correct and 100% ensured

Placements.

1. Model: CHMT48VA

Specially Design with Vision Based Pick & Place to achieve more

accuracy and ensure for correct Placements on Large Size of

PCB/SMT/LED from Small to Max Size of Components and PCB Size.

2. Top Vision Camera to Identify PCB and Types of Components,

Optimised Data with Programs File

3. Bottom Camera Check each components before placements, it can

check correct types of components, correct angle, correct

direction, flip components and wrong pick Up, Missed components.

4. Vision system sending inspected data and feedback to Programming

processor, Programming Processor give optimised command to machine

get the correct and 100% ensured Placements

5. Two Mounting Heads Provide high Throughput on High Mix Products

1. Placements Accuracy ±0.025mm for SMT/LED Components

2. Laser Pointer scale for correct teaching of PCB Origin,

Components Locations identifications and Nozzles Centring

3. On the Head Vacuum Detection system to detect components

4. High Quality & Spring Loaded Pick Up Nozzles to get the pickup

Flexibility of sensitive components

5. Integrated Components Reel Rack Slots and Holder

6. Max PCB Size: 380mm x 415mm

7. Lowest PCB Size: 10mm x 10mm

8. 20mm Components Height give flexibility for placements all types

of components

9. Components Handling Capacity from 0402 to 0603, 0805, 1206,

1210, 1812, 2010, 2512, 3216, DO-214, SOT23, SOT-89

10. Chip Tantalum Capacitors C-form(6032), D-form(7343) etc.

package components11

12. High Placements Speed up to 7200 Components/Hour

1314. Placements Angle from 0-360Deg Cent

15. Removable 8GB Memory Card for Back of Programs and Interface

with Laptop or Desktop Computer

16. Fully Touch Screen Operational Panel for easy Operation

Specifications of CHMT48VA:

Technical Parameter for CHMT48V | Dimension | L 960mm*W 705mm*H 335mm |

PCB Area | 10*10~355*355mm | |

XY Axis travel | 400*460mm | |

Z axis move range | 15mm | |

Pick and Place head | 2pcs | |

Mounting Speed | With vision 3000~4000cph; without vision | |

Working Precision | ±0.025mm | |

Stack | 8mm=22 stack; 12mm=4 stack; 16mm=2 stack; | |

Vacuum pump | 2pcs in-build (mute) | |

Vision system | Up view and down view dual cameras | |

Computer system inside | Linux system inside, very stable, no need external PC | |

Software to genterate CSV file | By Protel 99SE ; Altium Designer | |

Support files | .csv file | |

Touch screen | 7’’ (15.6cm*9.3cm) industry touch screen | |

Support packages | 0402,0603,0805,1206,1210,3528,5050, SO-16,SOT-23,SOT-89,TO-252,SOP,QFN, LQFP....different kinds of IC (max size 22*22mm) | |

Voltage | AC 110V/ 220V, 50/60HZ (supply the plug for your country) | |

Gross weight | 73kg (with wooden box packing) | |

Competitive Advantage:

1. Convenient system, computer windows7 inside the machine, independent operation, no need external computer,

operation more easy and convenient.

2. 7’’ TFT touch screen, it can connect a external USB mouse on the

usb port to operate the machine like a computer.

3. Top and bottom two cameras correct the position of each components very accurate, especially for IC.

4. It has flexible PCB clamping fixture, user-defined from stack NO.80. convenient and quick.

5. The vision also can second correction machine origin point, make

sure origin point correct.

6. With two nozzles placing heads, high precise Juki Nozzles with

magnet, no need to disassemble with wrench. 2 nozzles arbitrary rotation angle -180 degree~ +180 degree. Placing height can adjustable, accuracy of 0.1 mm.

7. PCB by two visual calibration, first and last componet, amend

the offset of PCB.

8. Calibration can be rapidly and accurately for PCB, do not need

to care about offset, no need to calculate the input.

9. Comes vacuum testing, with automatic feeding; if one component

suck crooked, it will automatically throw it to the feed zone, then

pick a new one to mount again.

10. If lack material it will automatic detection, then alarm; after

supply the material then continue working, no need to re-start.

11. Support any number of PCB batch.

12. If no PCB file, or don’t use protell software, you can creat a

new file to program. Support single step.

Applications industry:

Household appliances industry, Auto electronics industry, Power

industry, LED industry, security,instruments and meters industry,

communications industry, intelligent control industry, Internet of

Things(IOT) industry and military industry, etc.

Standard Accessories for CHMT48VA:

1) Pick and Place MachineCHMT48VA: 1

2) Juki nozzle: Totally 4pcs (503, 504, 505, 506 size)

3) 8G USB flash 1

4) Power Cord: 1

5) Pull pins: 2

6) Coil for pull pin:1

7) Camera positioning adjust black board: 1

8) Hex wrench: 6

9) Tweezers: 1

10) Brush: 1

11) English user manual: 1

Top and Bottom camera, make sure each component place very

accurate:

User-defined IC Tray:

Home page screen (touch screen):

Stepper motor with encoder, never loose steps:

Tools kit

Juki Nozzles total 4pcs:

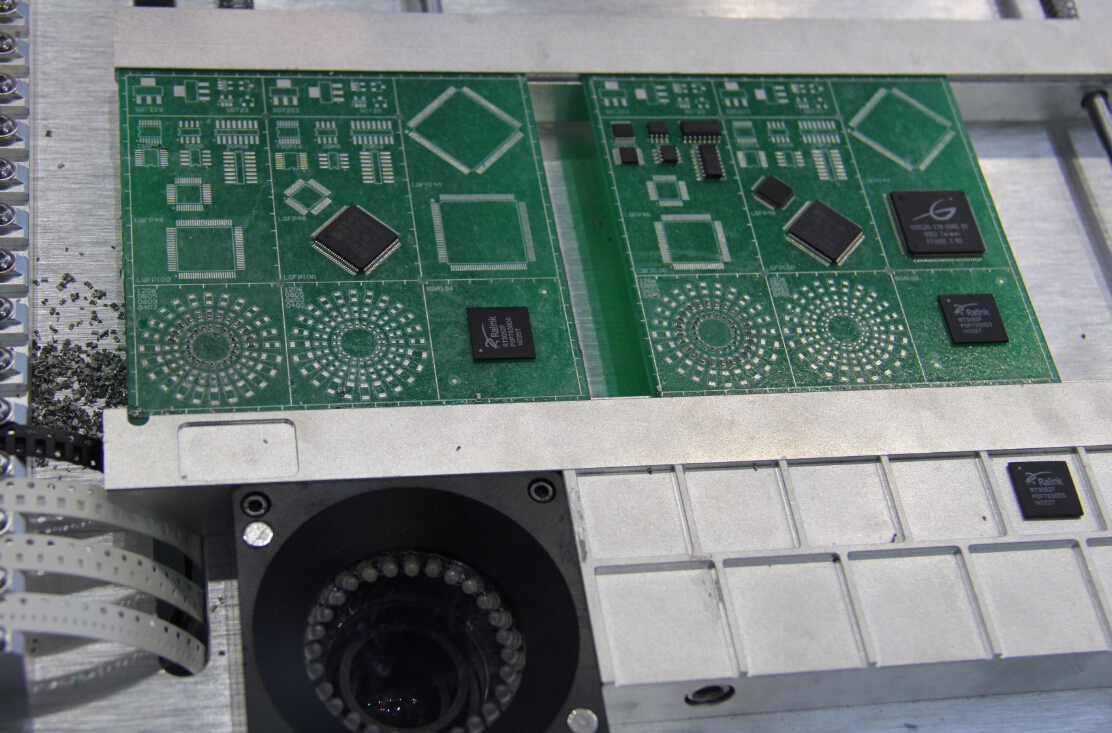

Sample:

Factory testing:

Warranty:

The complete machine has a warranty period of 1 year from the time

of purchase and lifelong service

support as well as a long term factory price supply.

We provide online Q/A and troubleshooting support and technical

advice service.

Provide one to one after-sale service. Each machine 100% test well then sent out.

Tech support:

Kimi Mob: 0086 135 106 75756

Skype: kimiliu89 .

E-mail: kimi@charmhigh-tech.com

|